DOSBAS® Introduction

Battery Packs for HEV/EV

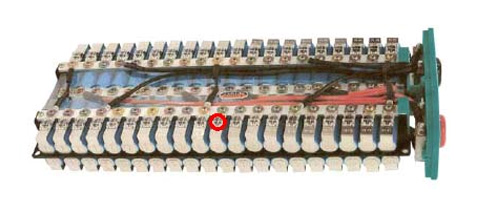

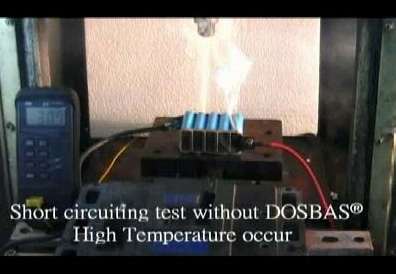

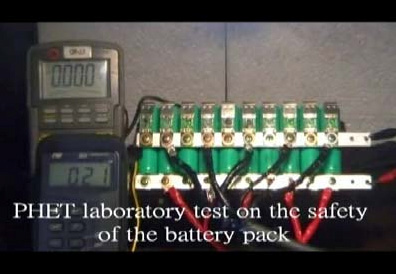

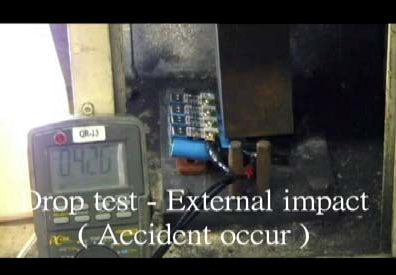

As described in the introductory section, the DOSBAS® battery system could isolate any over-heated cell(s) caused by internal short-circuiting via a fuse device, and, it certainly would help salvaging the normal cells from thermal runaway of the system. Figure 4 shows the photographic picture of an example of DOSBAS® battery system with the outer casing removed. In the picture, the red circle illustrates a fast-blown fuse with a LED indicator being connected to a standard cell inside the system. The system could not only prolong the cycle life of the battery pack also prevent injury to the occupants by blocking damaged cells due to external impact accidents. Because of the simplicity in structure, the DOSBAS® battery system has been proven to be able to withstand vibration and weather conditions by putting the system without casing through 150 hours in a salt mist chamber. For benchmark comparisons shown in Fig. 5, a battery pack was put to a short-circuiting test with final thermal runaway temperature reaching at 309 degrees C. The results would be devastating if a large number of cells were assembled into a battery system. However, a DOSBAS® battery pack safely passed the short-circuiting test with no temperature increase and cell damage as shown in Fig. 6. As a further step, a DOSBAS® battery pack was drop-tested to simulate external impact forces as shown in Fig. 7. In this case, no thermal runaway was noted with fuses blown by the damaged cells and low residual pack voltage.

Ultimately, a fleet of twenty-three electric vehicles has been road-tested with an average mileage of 9,868 km in Asia and Europe from August 2007 to January 2009. Figure 7 shows one of the EV being road-tested in Taiwan. The EVs have been assessed under various weather conditions for road performance, life expectancy, and safety reliability. It should be further noted that by installing a voltage balance board (VBB) between the positive and negative terminals of each battery pack for overcharge prevention, a battery management system (BMS) for charging and discharging status management is redundant. Hence, none of the twenty-three EVs in the fleet has been equipped with the BMS. Up to date, the test results have comprehensively proven that all the battery packs successfully retraced the expected retained capacity compared to the testing conditions in the laboratory. The above results are obtained by periodically sampling standard 18650 cells from the test fleet for laboratory analysis.

As a further step, on one of the vehicles with accumulated mileage over 15,000 km, a handful of standard 18650 cells, parallel connected inside different battery packs, from the battery packs were purposely replaced with new cells typically with lower impedance. The preliminary results have shown that the new cells blended into the existing battery packs without a noticeable change in the autonomy per charge on the vehicle even though the new cells are lower in impedances. It is evident that the above treatment could be very challenging for battery packs consisting of large-format cells without protection device on the cells. Helped by the DOSBAS® battery system, replacement of battery cells damaged by internal short-circuiting or depleted in early cycle-life could be practically accomplished. It is still debatable that with the help of today’s most advanced BMS, battery systems consisting of large-format cells would require cumbersome services for cell replacement. After going through available tests in the factory, the DOSBAS® battery system has been proven to be one of the most promising battery systems for electric vehicles today.

|

|

| Figure 4 Photographic picture of a typical battery system with casing removed for showing a protection device in series with each cell; the device being indicted by a red circle. | |

|

|

| Figure 5 Photographic picture of a battery pack assembled with 10 cells in C-LiFePO4 chemistry being short-circuit tested with thermal runaway results; the final cell temperature being at 309 C as indicated on the thermometer. | Figure 6 Photographic picture of a DOSBAS® battery system assembled with cells in C-LiFePO4 chemistry being short-circuit tested with no increase in cell temperature and visible cell damage except the blown fuses. |

Figure 7 Photographic picture a DOSBAS® battery pack safely passed the drop-test for simulating external impact forces; 0.426 volt of residual voltage being measured on the pack. Figure 7 Photographic picture a DOSBAS® battery pack safely passed the drop-test for simulating external impact forces; 0.426 volt of residual voltage being measured on the pack. |

Figure 8 Photographic picture of an electric car powered by the DOSBAS® battery system configured for 72V and 120AH under the hood. Figure 8 Photographic picture of an electric car powered by the DOSBAS® battery system configured for 72V and 120AH under the hood. |